What is OSHA’s Focus Four and which controls can we implement to mitigate the risk?

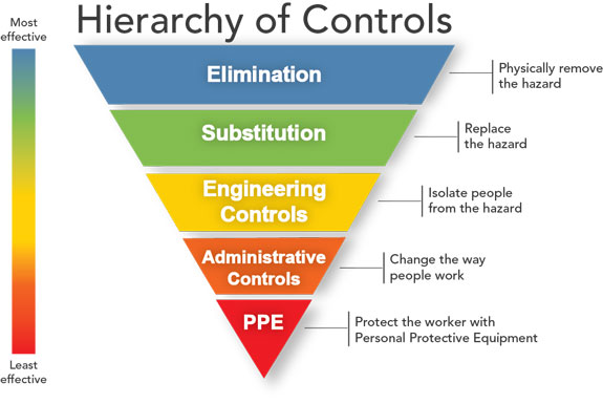

In the world of safety and health management systems (SHMS), safety professionals control worker exposure to hazards using a systematic approach.

The old hierarchy approach was to start with implementing an engineering control, followed by an administrative control, and ending with what we call the last line of defense a personal protective equipment (PPE) control. In 2015, the National Institute for Occupational Safety and Health (NIOSH) updated the hierarchy of controls. The model looks like the following image:

OSHA developed the Focus Four initiative in 1994 to target the top four safety hazards in construction:

- Falls from heights

- Struck by

- Caught in between

- Electrical shock

The source for this information was provided by the Bureau of Labor and Statistics (bls.gov) which is tasked to collect workplace injury statistics. These four hazards produce the overwhelming number of construction fatalities and injuries.

Focus Four Number One: Falls to lower level

Falls are the leading cause of death in construction. In 2020, there were 351 fatal falls to a lower level out of 1,008 construction fatalities (BLS data).

Employers in construction are required to implement a fall hazard awareness training program. The program is required to train and educate workers who work at elevated heights of six feet or more below the lower level. And the training is required to be documented and certified. The trainer is also required to be qualified and competent in fall protection systems.

The OSHA standard requires the training include the following:

- The nature of fall hazards in the work area

- The correct procedures for erecting, maintaining, disassembling, and inspecting the fall protection systems to be used

- The use and operation of guardrail systems, personal fall arrest systems, safety net systems, warning line systems, safety monitoring systems, controlled access zones, and other protection to be used

- The role of each employee in the safety monitoring system when this system is used

- The limitations on the use of mechanical equipment during the performance of roofing work on low-sloped roofs

- The correct procedures for the handling and storage of equipment and materials and the erection of overhead protection

- The role of employees in fall protection plans

- The standards contained in 29 CFR 1926 Subpart M Fall Protection

The fall protection training includes engineering, administration and PPE controls. See OSHA’s Fall Prevention Campaign | Occupational Safety and Health Administration

Focus Four Number Two: Struck by

A struck-by hazard refers to an accident/incident in which a worker is hit and injured by an object, tool, or piece of equipment. Struck-by hazards are mostly related to improper material and equipment handling as well as poor housekeeping. Struck-by hazards originate from many sources. Struck by hazards on average produce the second most fatal outcomes. This hazard exposure is the leading cause of nonfatal injuries in the construction industry.

There are limited OSHA standards that address struck by hazards. In January of 2022 OSHA had investigated 15 struck by fatalities. The two leading causes for struck by fatalities were dropped objects and mobile equipment.

Controls for struck by exposures could include implementing a drop zone program (engineering and administrative control) and providing workers with reflective vests and hard hats (personal protective equipment).

In April of 2019, the National Occupational Research Agenda (NORA) created the National Stand Down To Prevent Struck By Incidents initiative to help bring awareness to this hazard. CPWR | Struck-By Hazards

Focus Four Number Three: Caught in between

This categorization includes construction workers who are killed when caught in or compressed by equipment or objects, as well as the hazards of being struck, caught, or crushed in a collapsing structure, equipment, or material. On average caught in between injuries are the third most common in construction.

The primary caught in between exposure in construction is a trench collapse. Dirt is heavy. A cubic yard of class C soil can weigh on average as much as a midsize car.

On July 14, 2022, OSHA issued a news release that stated the following:

”WASHINGTON – In 2022’s first six months, 22 workers have fallen victim to the deadly hazards present in trenching and excavation work – surpassing 15 in all of 2021 – and prompting the U.S. Department of Labor’s Occupational Safety and Health Administration to launch enhanced enforcement initiatives to protect workers from known industry hazards.

To stress the dangers of disregarding federal workplace safety requirements for trenching and excavation work, OSHA enforcement staff will consider every available tool at the agency’s disposal. These actions will place additional emphasis on how agency officials evaluate penalties for trenching and excavation related incidents, including criminal referrals for federal or state prosecution to hold employers and others accountable when their actions or inactions kill workers or put their lives at risk.”

Employers are required to implement a cave in protective system (engineering control) in a trench which is deeper than it is wide and when the depth reaches five feet. OSHA also requires a competent person (administrative control) to manage a trench/excavation job site.

OSHA has had a National Emphasis Program (NEP) directive in place since 2018 which describes how the enforcement agency will address the hazards of a trench. See https://www.osha.gov/sites/default/files/enforcement/directives/CPL-02-00-161_0.pdf

Some additional caught in between hazards are:

- Exposure to rotating equipment

- Unguarded parts

- Equipment rollovers

- Caught between the counterweight of the crane and another structure

Focus Four Number Four: Electrical shock

Electrocutions are the fourth leading cause of death among construction workers in the United States. An average of 143 construction workers are killed each year by contact with electricity.

Electrical workers had the most electrocutions per year, followed by construction laborers, carpenters, supervisors of non-electrical workers, and roofers according to bls.gov.

Contact with overhead power lines or live circuits in panels, poorly maintained cords and tools, and lightning strikes are the main electrical hazard exposures. More than 70% of those killed were not electricians. Overhead power lines are the main killers.

You can be killed instantly if you are using the following equipment and it encounters an overhead power line:

- Aluminum extension pole for paint rollers

- Backhoes and cranes

- Concrete pumpers

- Long-handled cement finishing floats

- Metal ladders

- Raised dump truck beds

- Scaffolding

Electrocution occurs when a person is exposed to a lethal amount of electrical energy. Electric shock occurs upon contact of a body part with any source of electricity that causes a flow of current through the skin, muscles, or hair. The resulting injuries could be heart attack, thermal burns, and amputation.

To avoid shocks and electrocution, workers must be mindful of hazards such as contact with power lines, contact with energized sources and improper use of extension and flexible cords.

Maintain a safe ten-foot minimum distance from overhead power lines (administrative control), use ground-fault circuit interrupters (GFCI) (an engineering control), inspect portable tools and extension cords (administrative control), using power tools and equipment as designed, and follow lockout/tagout procedures (administrative control). There are a handful of OSHA standards that address the hazard of electricity.

For more information go to Electrical – Overview | Occupational Safety and Health Administration (osha.gov)

Safety managers, field supervisors, foremen, and other safety workers should be aware of the Focus Four on a daily basis and address those hazards in their pre job risk assessments.

For more information: Construction Focus Four Training | Occupational Safety and Health Administration (osha.gov)

Reducing Risk with Safety Professionals from ResponsAble

Struggling to find qualified safety professionals for a contracted or direct hire position? As expert safety recruiters, we help you get the job done. ResponsAble is the safety recruiting company that helps you find the right people with the necessary skills to effectively and safely complete the job. Big or small, temporary or permanent. For more information, please submit a contact form here.